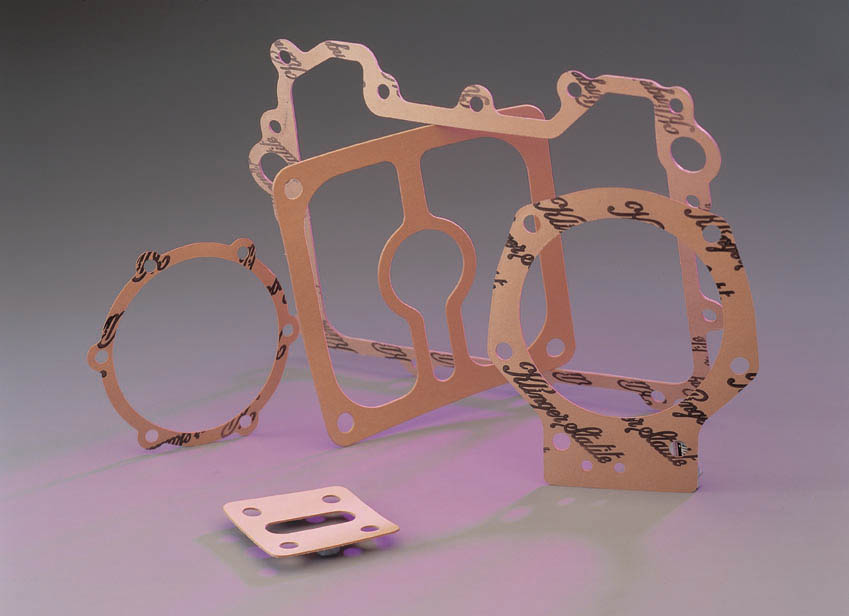

It is a gasket material based on glue-bonded, impregnated cellulose fibers.

Application

- In transmissions, carburettors, fuel and oil pumps, axles

- For sealing fuels, oils, water, mixtures of water & antifreeze and corrosion inhibitors

| CARACTERISTIC | VALUE | RULE | |

|---|---|---|---|

| Density | g/cm³ | 0.7 – 0.9 | |

| Tensile strenght (thickness 1.5 mm) | |||

| acc. to ASTM F 152 | across grain | N/mm² | > 20 |

| acc. to DIN 52 910 | across grain | N/mm² | > 15 |

| Compressibility and recovery | |||

| acc. to ASTM F 36, procedure G | |||

| compressibility | % | 20 – 40 | |

| recovery | % | > 35 | |

| Swelling acc. to ASTM F 146: | |||

| in IRM 903 Oil (replaces ASTM Oil No. 3) | |||

| 22 h, room temp. | |||

| Increase in thickness | % | < 5 | |

| increase in weight | % | < 20 | |

| in ASTM Fuel B | |||

| 22 h, room temp. | |||

| increase in thickness | % | < 5 | |

| increase in weight | % | < 15 | |

| in water / antifreeze (50:50) | |||

| 22 h, room temp. | |||

| increase in thickness | % | < 30 | |

| increase in weight | % | < 95 | |

| Maximum operating temperature | ºC | 120 | |

| Maximum operating pressure | bar | 10 | |